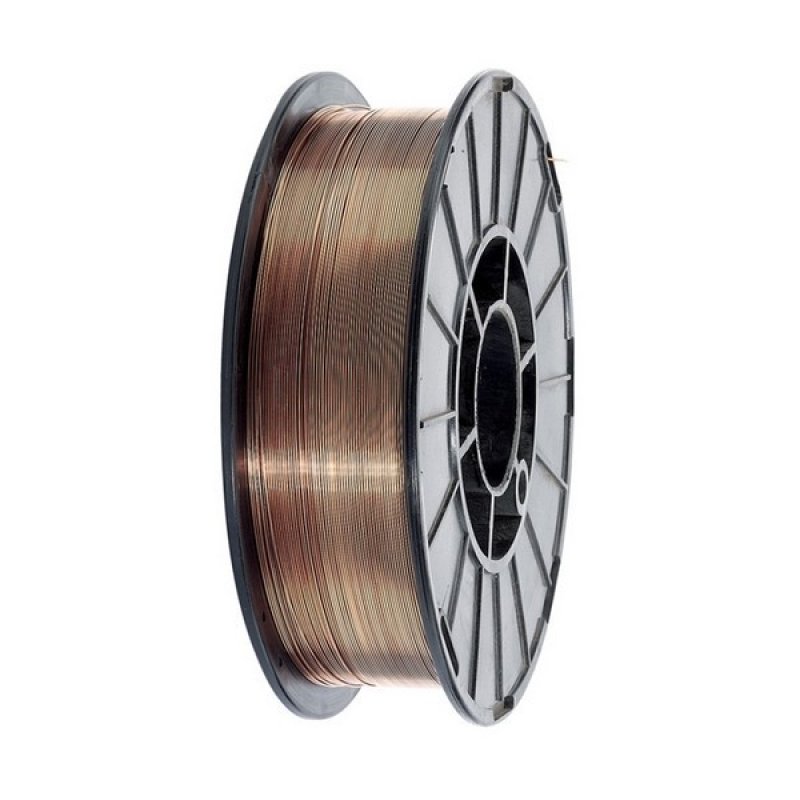

Copper-coated welding wire of 0.8 mm for welding unalloyed and alloyed steels, ideal for bodywork repair.

High-quality welding wire for various applications

The LASKAR welding wire of 0.8 mm is specially designed for welding unalloyed and alloyed steels. Thanks to the copper coating, this wire offers a stable arc and minimal spatter, resulting in high-quality welds.

Ideal for bodywork repair

This welding wire is particularly suitable for repairing bodywork damage. The fine diameter of 0.8 mm makes it possible to create precise and neat welds, essential for maintaining the structural integrity and aesthetics of cars.

Technical specifications

- Type of welding wire: SM-70 eco

- Standards:

- AWS A 5.18 / ASME SFA5.18: ER 70S-6

- EN ISO 14341-A: G 42 4 C1/M21 3Si1

- JIS Z3312 YGW12

- Certification: CE approved

- Diameter: 0.8 mm

- Packaging: 15 kg

Advantages of copper-coated welding wire

- Improved electrical conductivity: The copper layer ensures more efficient current transfer during welding.

- Reduced wear: Copper coating reduces wear on welding equipment, extending its lifespan.

- Better corrosion resistance: The copper layer provides extra protection against corrosion, increasing the durability of the welding wire.

Areas of application

- Automotive industry: Ideal for welding bodywork and chassis components.

- Machine construction: Suitable for joining various steel structures.

- Shipbuilding: Applicable for welding ship parts and structures.

Compatibility with shielding gases

This welding wire is suitable for use with both CO₂ and mixed gases (for example, 80% Ar + 20% CO₂), offering flexibility depending on specific welding conditions and desired results.

Mechanical properties

- Tensile strength (Rm): 540 N/mm²

- Yield strength (Rp 0.2%): 430 N/mm²

- Elongation (A5): 24%

- Impact values:

- At 20°C: 150 J

- At -40°C: 90 J

With the LASKAR welding wire of 0.8 mm, you have a reliable and versatile solution for various welding tasks, especially in the automotive sector.

Specifications

Maybe you are also interesed in:

CEWELD welding wire 0.6 mm for unalloyed steel

LASKAR welding wire 0.8mm for bodywork repair

LASKAR welding wire 1.00 mm for unalloyed and alloyed steel

Stay up to date with the latest news and promotions!

Subscribe to our newsletter

Dutch

Dutch

French

French